Service and Assistence

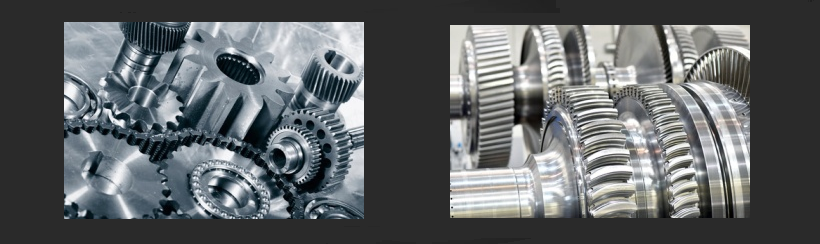

Relying on highly-qualified staff and partners with proven technical experience in specific fields, GMU’s strength is in its promptness and swift interventions to solve its customers’ problems, enabling to minimize possible machine-stops. We carry out ordinary and extraordinary programmed machine maintenance work, trying to satisfy the customer’s needs. Accordingly to our needs as well as our customers’ we rely on specialized firms in order to offer our customers a reliable and efficient service. We can move entire machine tools turn-key relying on our partners for carrying and transporting the machines. GMU Machine Tools can offer a wide range of maintenance interventions on industrial machines such as: - First-rate mechanical and electronic REPAIRS on any kind of machine tools (lathes, milling machines, grinding machines, workstations, drilling machines and automation systems). All maintenance interventions can be carried out either in our workshop or at the customer’s. A wide range of spare parts is also available for our customers. - Complete machine tool OVERHAULS involving dismantling, painting, reboring, building and replacement of worn-out parts; substitution and installation of electrical systems in compliance with EU requirements and warranty new. - Retrofitting for lathes, mills, grinders and workstations of any make and of any kind, also for CNC machine tools of the most famous building brands. All maintenance interventions are carried out scrupulously, including internal projecting and programming of the switchboard and PLC. Our workshop has a large quantity of spare parts in stock, both new and overhauled, for CNC machine tools.